Warehouses, Loading Bays & Ramps

Large concrete warehouse floors are prone to dust from unsealed surfaces, which can create multiple hazards for the facility, operations, and staff.

In situations the dust can cover, enter and damage important manufacturing equipment. Inhalation of dust can also cause health risks to employees, making it a liability for the company. It is is critical you consider all options available when accessing your warehouse floors.

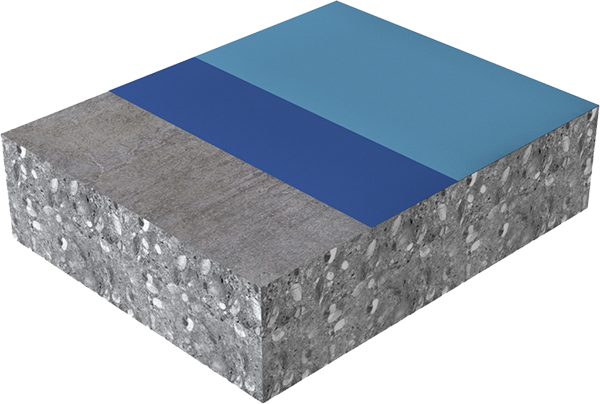

A number of coating options are available, clear liquids applied to the surface as dust proofers or coloured coatings that provide hard wearing surfaces with high abrasion, impact and good chemical resistance.

Coloured walkways and non-slip areas eg ramps, working stations are also important components when considering coatings for your warehouse floor.

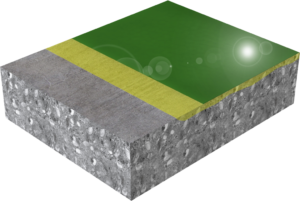

A 2-Part, economic, solvent-free coloured epoxy resin.

USES:

Roller coat for concrete and cement screeds with normal up to medium heavy wear e.g. storage an assemble halls, maintenance workshops, garages, loading ramps. Seal coat for broadcast systems, such as multi-story and undercover care parks, maintenance hangers and for wet process areas e.g. beverage and food industry, warehouse, vehicle showroom, dry areas, hangers and laboratories.

CHARACTERISTICS:

Good chemical and mechanical resistance, economical, solvent free, gloss finish and slip resistant surface possible.

SPECIFICATIONS:

- High wear and abrasion resistance

- Good impact resistance

- Good chemical resistance

- Medium thermal resistance

- Easy cleaning

- Coloured

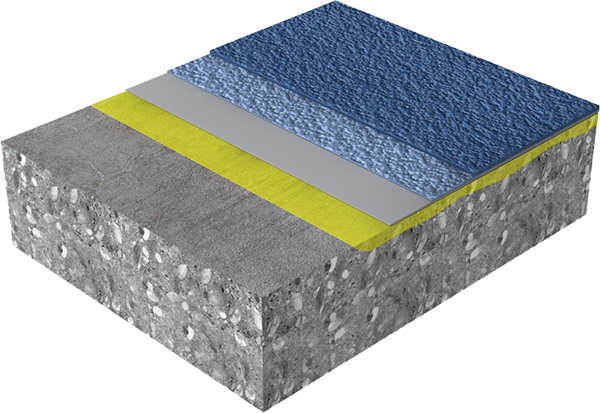

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-156/ -161

Coating: Sikafloor-264, a two part, total solid, coloured, epoxy binder.

Total layer thickness: 600 – 800 microns

Is a thisotropice 2-component solvent free pigmented 100% solids high build epoxy coating for heavy duty and decorative finishes for walls and coves in addition to providing a textured floor coating.

USES:

Food processing industry, plastics industry, laboratories, aircraft hangers and workshops, washrooms, cloakrooms, chemical/pharmaceutical industries.

CHARACTERISTICS:

High mechanical properties, good abrasion resistance, high durability, coloured, joint less, easily cleaned and maintained, waterproof.

SPECIFICATIONS:

- High wear and abrasion resistance

- Good impact resistance

- Good chemical resistance

- Medium thermal resistance

- Easy cleaning

- Coloured

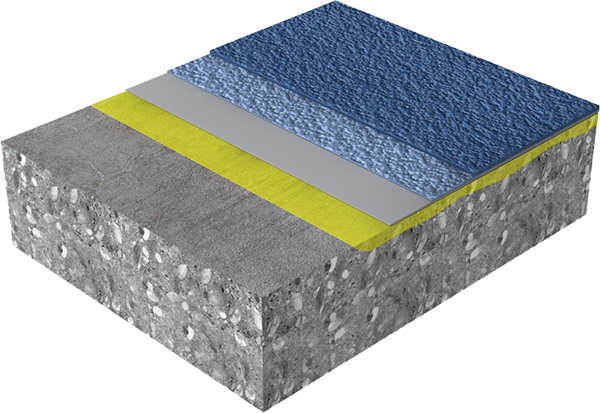

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-156/-161

Coating: Sikafloor-264 SL, a two part, coloured epoxy binder for self-smoothing screed systems.

Total layer thickness: 1-3mm

Is a thixotropic 2-component solvent free pigmented 100% solids high build epoxy coating for heavy duty and decorative finishes for walls and coves in addition to providing a textured floor coating.

USES:

Food processing industry, plastics industry, laboratories, aircraft hangers and workshops, washrooms, cloakrooms, chemical/pharmaceutical industries.

CHARACTERISTICS:

High mechanical properties, good abrasion resistance, high durability, coloured, joint less, easily cleaned and maintained.

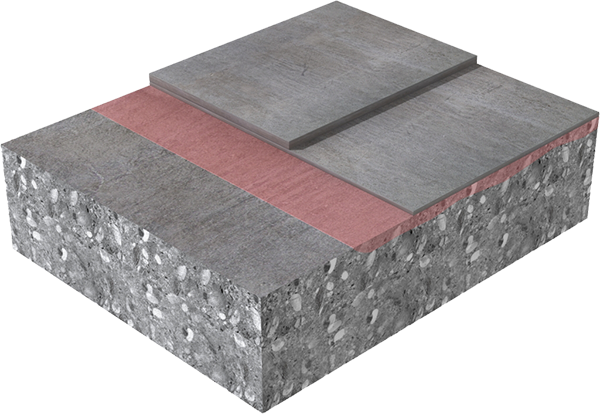

SPECIFICATIONS:

- For surface damaged cementitious floors

- Reduced waiting time to overcoat green concrete

- No blisters on topping when coating damp concrete

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-155 WN

Screed: Sikafloor-81 EpoCem,

three component epoxy modified cementitious, self-smoothing screeds.

Topping: Sikafloor resin to suit

Total layer thickness: 2-3mm

CHARACTERISTICS:

Self-smoothing, temporary moisture barrier on “green” damp concrete.

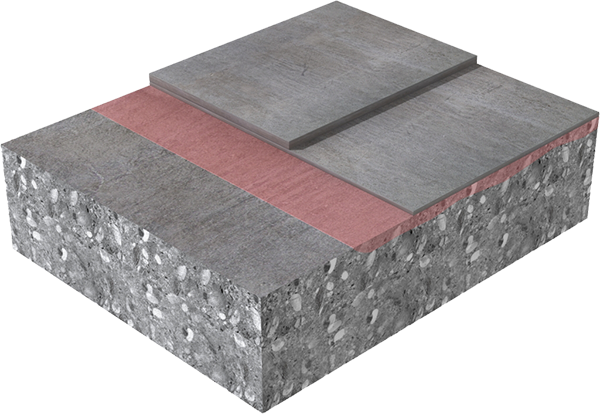

SPECIFICATIONS:

- For concrete floors with damaged or missing DPC membrane

- No waiting time on “green” or damp concrete

- No blistering in the finish when coating damp concrete

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-155 WN

Base coat: Sikafloor-81 EpoCem, three part epoxy modified, cement based, self-smoothing screeds

Topping: Sikafloor resin system to suit

Total layer thickness: 2-3mm

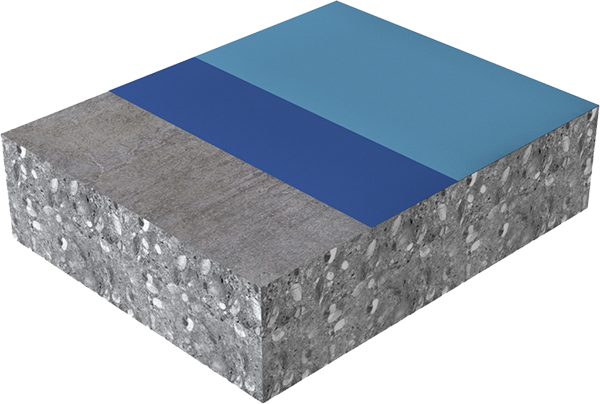

Two part, water dispersed, solvent free, coloured, epoxy resin based coating.

USES:

Coloured epoxy coating for concrete, cement screeds, broadcast systems and epoxy mortars. Workshops, warehouses, garages, walk ways.

CHARACTERISTICS:

Good chemical and mechanical resistance, water vapour permeable, water dilutable, odourless and easy application.

- Medium wear resistance

- Surface stabilization

- Prevent concrete dusting

- Coloured

- Low odour

SIKA SYSTEM / PERFORMANCE:

Coating: 2 x Sikafloor-2540 W, a two part, water dispersed, coloured, epoxy resin based coating.

Total layer thickness: 150-250 microns

Is a clear two-component, water dispersed epoxy resin.

USES:

As a clear sealer for concrete floors that are subjected to light wear and abrasion. Workshops, warehouses, garages, walk ways, walls.

CHARACTERISTICS:

Reduces dusting, low odour, economical and reduces permeability.

SPECIFICATIONS:

- Prevent dusting

- Seal concrete surface

- Very low VOC

SIKA SYSTEM / PERFORMANCE:

Sikafloor Duroseal W, a 2-part, water based epoxy.

CHARACTERISTICS:

Clear surface harder for concrete.

SPECIFICATIONS:

- Economic surface hardening

- Good abrasion resistance

- Prevent surface dusting

- Curing to ASTM C-156

SIKA SYSTEM / PERFORMANCE:

1 – 2 x Sikafloor Curehard-24, a sodium silicate based liquid hardener sprayed and brushed into the substrate

OR

1 – 2 x Purigo 5S, a sodium silicate based liquid hardener sprayed and brushed into the substrate.

Is one component, non-yellowing, aliphatic, moisture curing, and polyurethane gloss coating containing UV light absorbers.

USES:

Ideal for interior and exterior seamless floors, concrete sealer and suitable as an aggregate glaze for embedding nonslip aggregates.

CHARACTERISTICS:

Flexible and heat resistant, one component moisture curing, clear, non-yellowing, high gloss and matt finish option, tough, hard wearing, Good chemical resistance and excellent abrasion resistance. Ideal for Warehouse, exposed concrete and vehicle showrooms.

CHARACTERISTICS:

Ramps – Flexible.

SPECIFICATIONS:

- High abrasion resistance

- Waterproof

- Thermal exposure

- Static crack-bridging

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-156/-161

Wearing layer: Sikafloor-375 (Extender T) broadcast with Quartz sand.

Seal coat: Sikafloor-359N

Total layer thickness: 3-4mm